Abbott Analytical Products

Reference:

Brass Credit Card:

Brief Summary of Project:

From 2022: (FreeCAD and LinuxCNC) A friend requested the fabrifcation of a credit card formatted nameplate for one of our mutual

associates. Having gained experience since the 2018 Brass Nameplate project, FreeCAD was employed for

design and generation of gcode.

FreeCAD is an opensource CAD tool that allows the design of objects and subsequent gcode (program for executing

the actual LinuxCNC milling of the object.

| Image

| Comment

|

|

This image shows the final delivery of the Credi Card Style nameplate. The design was rendered

using FreeCAD 18.4 running under Ubuntu 16.04 (64Bit). The FreeCAD design artifacts and final

gcode programs are available for downloading form the GitHub link given below.

https://github.com/trooker/credit_card_style_3line_nameplatete

|

|

Lower Level Detail

|

|

FreeCAD View

|

Snapshot From FreeCAD Design

| Image

| Discussion

|

|

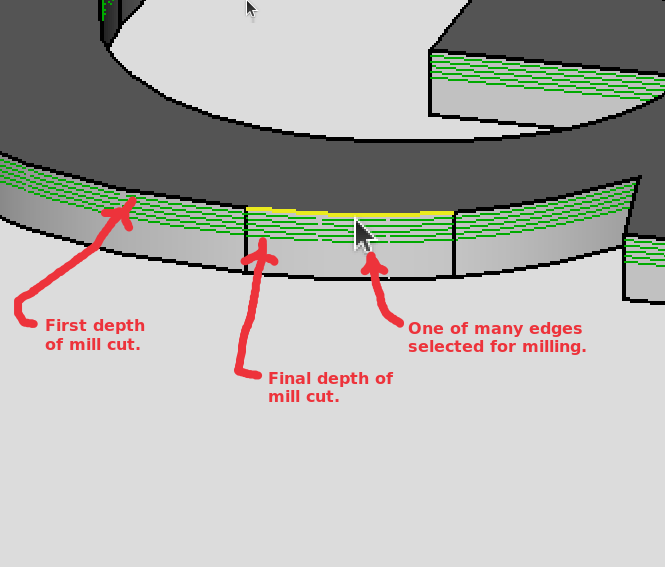

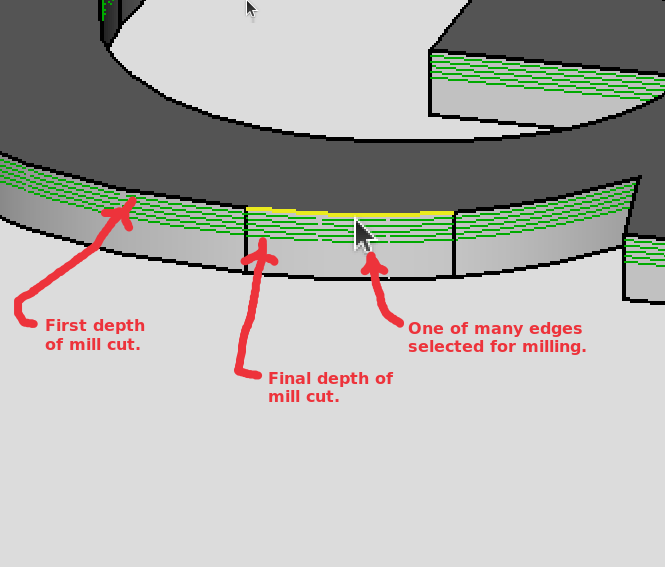

These images are of the "Engrave" task definition showing the "G" of the third line. In this instance

the designer has elected to sequnetially "highlight" one of the 1324 endges required to define

the three lines of charcters. The image also shows the "Engrave" task five depths that FreeCAD

rendering of the design created. This rendering yielded the first gcode program for milling the

Credit Card Three Line design.

|

|

|

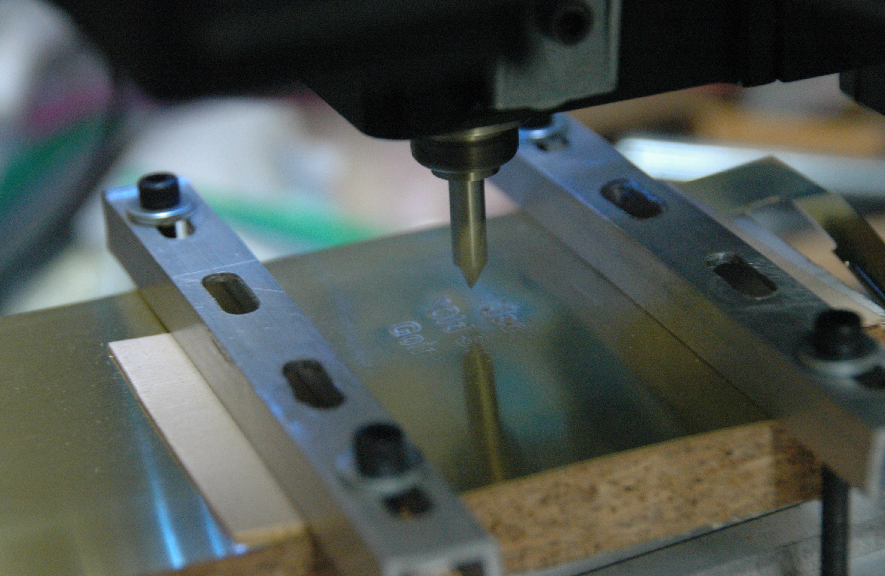

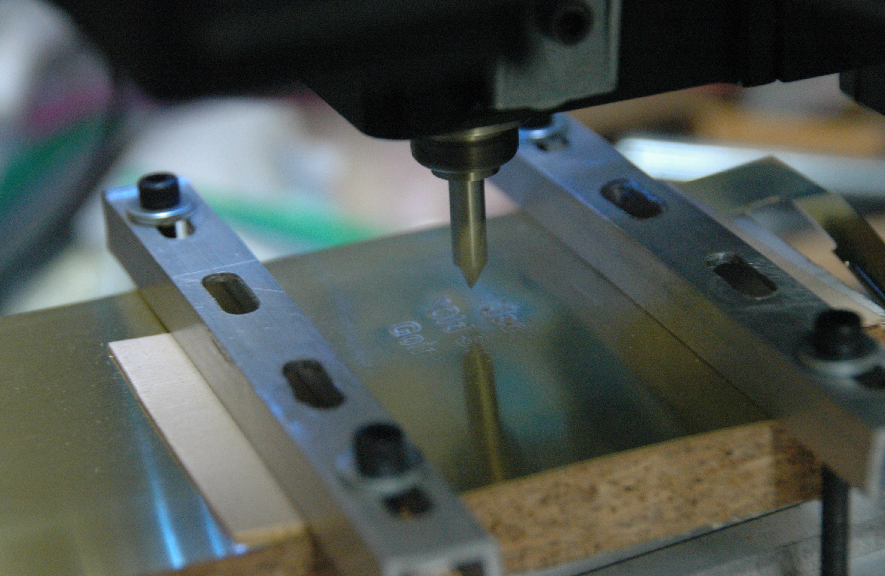

This image displays the LinuxCNC program driving the FreeCAD produced gcode on a Sherline

8580 NexGen CNC in a simulation mode. The engraving bit sat idle while the user observed the

simulation run.

Based upon the simulation run a decision was made to "modify" the original FreeCAD gcode. The

modification employed various used defined variable for x-, y-, and z-axis speeds, a "safe height

to which the bit was raised in the z-axis for relocation. The modification also consolidated the

actual engrave loop for milling the three lines of text.

|

|

First pass using the engraving bit used for projects in 2018 and 2019. This first attempt was rule

unacceptable quality. That led to a search for a "tighter" engraving bit using the same edges.

Introducing the new Dremel Engraver tool to the project required a new entry in the tooltable and

minor changes to FreeCAD artifacts as well as the gcode.

|

|

Helpful Approaches

|

These modifications greatly improved the original gcode from FreeCAD

|

Flatness Check

|

A gcode program was written which verifies that the four corners of the brass stock are flat

with material secured using the project hold-down fixturing. This project's flatness test reuses

gcode fragemnts from the Fishing Lure lip checks.

|

Major Tweak to gcode

|

The original FreeCAD engrave process for the three lines of textrequired 6196 separate movements

to make five separate levels of depth cuts. In other words the engraving bit would would follow

the same path to create the three lines of text five separate times. The only difference would be the

increasing depth to which the engraving bit would plunge. Using the LinuxCNC subroutines

to control the program flow (the movement of the engraving bit) an engraving loop was created

using "one pass" of the original FreeCAD gcode and a logic while less than to check to see which

loop to do next or to break-out of the loop.

This essentially allowed a "single step through a depth, halt, check". In that manner when the results appeared

to be "satisfactory" the milling phases was terminated.

|

Results

|

The final approach that was found to be helpful during the actual milling of the Credit Card

Style Nameplate was adding the same type of "single step through a depth, halt, check" approach

was implemented for the Contour-Fillet-Tab to generate the appearance of the credit card style.

|

|

|

|

Brass Nameplate:

Image 2019: Second Brass Design Production demonstrating movement down learning curve.

In 2019 the usage of FreeCAD replaced pyCAM and HeekCNC. Two different engraving styles and bits

were employed to allow client to select preferred style. Finaly, c-shaped adjustable hold-down brackets

greatly improved fabrication quality. FreeCAD provided a "Tab" contouring feature that gave extra control

during the final milling.

Brief Summary of Project:

From 2018: (OpenSCAD/PyCAM/HeeksCNC/LinuxCNC) A brass nameplate for use on the display of a model of the USS Constellation was milled. It was a

simple three line affair with two drill holes of brass tacks set on a thin oval brass blank. It was a very real learning experience

in homing, tool heights, work offsets, tabs, and Heeks CAD/CAM tool. There were multiple runs made in wood and scrap copper. But

there was only one piece of scrap brass created. That run demonstrated the need for tabs as the holddown fixturing failed. The final run was a step process

involving three tool changes. In order to do that at the skill level at that time, three separate NGC programs were sequentially run.

Image 2018: First Brass Design Prototype displaying hold-down failure and need for tabs.

From 2018: Discussion of Process Flow

The gcode shown below is ordered in the sequence used to mill the project. Note that that engrave and blank milling employed

the usage of user defined variables and o-code

flow control looping.

- Engrave text

- Center drill two holes along centerline of raw blank.

- Milling blank in four passes with tabs.

Tool Table Entries

- T4 P4 Z1.627 ;1/8 flat end mill 3/8 holder

- T5 P5 Z0.9975 ;center drill#2 in collet

- T7 P7 Z0.7865 ;router engrave bit collet

Design to gCode Process Flow

1> Use OpenSCAD to create ellipse shape.

2> Using the 2D shape export it as a SVG image from OpenSCAD.

3> Invoke pyCAM and set units to inches.

3.1> From the main bar menu select Edit -> Engrave text to obtain the

Engrave text

Wizard. Enter the text needed and

apply.

3.3> Push this "text" through the pyCAM process for Tools, Process, Bounds, Task, and Generate Toolpath. Then

Export the process engrave text model as an

ngc file from pyCAM.

4> Invoke HeeksCAD.

4.1> Import the SVG image (step 2 above) and extrude for solid shape.

4.2> Add the two drill holes as points.

4.4> Setup Drilling operations for the

two Holes.

4.5> Define the end mill tool (T4) and the center drill tool (T5)for cutting the blank shape using the values in the tool table given earlier.

4.6> Attempt to execute the Post-Process. If successful this activity will allow the creation of an gcode ngc file.

4.8> If desired, a text editor add user defined variables and o-code flow control looping to improve readability.

4.9> Using a text editor split the "blank/drill hole" ngc into two separate ngc files to facilitate tool changes.

5> For a trial run, open a LinuxCNC session (ideally on a simulator) engaging the stepper motors.

5.1> Load the appropriate tools to the tool table(T4, T5, and T7) to satisfy the newly created ngc gcode files.

5.2> Load the "blank" ngc gcode file to LinuxCNC, execute with the steppers engaged. Make the drill hole

tool change per the NGC. Finally, do not sweep away the "red" mill path lines.

5.3> Load the "engrave ngc gcode" and adjust position (using Touch Off G54 in X,Y axis) as needed to center the text box on the blank.

5.4> Inspect the "composite" engrave text box and the blank from the

Z-axis and

Y-axis.

7.1> Load the "blank" ngc gcode file to LinuxCNC, execute without the steppers engaged. Do not sweep away the "red" mill path lines.

7.2> Zero the

engraving ngc as in step 5.3 and execute using

step movement. Use the "step" through execution until comfortable with to very placement and depth of engrave text.

Plexiglass Heart:

(Veus/PyCAM/HeeksCNC/LinuxCNC) The classic heart shape was created in such a way as to be completely scalable in the XY plane. The

hearts have text. The first runs were executed in Plexiglas. After a number of prototypes, a suitable level of "quality" was

obtained to allowing gifting the resulting objects as tokens. The plan is to use the heart shape on a box lid eventually.

Image 2: Early prototype showing crude tab removal and poor junction points.

Discussion of Process Flow

The gcode shown below is ordered in the sequence developed/used to mill the project. Note that that engrave and blank milling employed

the usage of user defined variables and o-code

flow control looping. The Heart Blank goes one step further using

scaling in the XY plane.

Heart Blank Design Supporting Artifacts

- Spreadsheet rendering of the classic Heart Curve.

- SVG file exported from Veusz based on classic Heart Curve.

- HeeksCNC project file yielding gcode.

gCode for Milling

- pyCAM produced Engrave Text.

- HeeksCNC generated Milling Blank.

Tool Table Entries

- T7 P7 Z0.7865 ;router engrave bit collet

- T16 P16 Z2.27855 D0.1275 ;1/8 x 3/8 double 2 flute

Design to gCode Process Flow

Heart Component: A suitable set of equations representing the classic Heart Curve was found. A spreadsheet

was used to assmble a graph of the outline of the heart. The data points of the outlined heart were convert to a *.csv format. The

Veusz graphic tool was used to create an XY plot of the *.csv data. Once that was done the figure was exported as an *.svg file. The

*.svg file was imported to HeeksCNC. As an *.svg the heart shape is basically a 2D figure. But

before the heart shape could be used it had to have the extraneous Veusz introduced axis information removed. Once that was done

processing continued. There is no extrusion necessary for a 2D figure, since the same effect can be achived in a Profile Operation. After

setting the tooling and tabs gcode was generated. The "raw" gcode was modified to incorporate o-code program flow control. Scaling of

the XY was achived using global replacement.

Engrave Text Component: Prior engrave experince with pyCAM led to using that tool for the engrave text. A pyCAM session was started. The default model deleted

The the units was switched to "inches". The Edit bar menu item was sleected which resulted in "Engrave text" option becoming available.

Selecting the "Engrave text" option yielded the Engrave text wizzard. Add "Love" and select

Apply to create a new model, Text Love. Adjust the sizing as necessary. The 3D view should

now display. At this point the development to gcode should follow the typical tools, process,

bounds, task, toolpath simulate/export process to yield the appropriate gCode for the "Love" text.

Milling Time: Open a LinuxCNC session. Load and execute the Heart Blank gcode. Once that

set of code finishes load the Engrave Text. Inspect the Engrave Text to insure it is

placed as needed. Relocate/place the Engrave Text as needed using the Touch Off button

process for X/Y axis for P1 G54. When satisfied execute.

Simple Wooden Fishing Lure:

Brief Summary of Project:

(OpenSCAD/HeeksCAD/CNC) Simple Fishing Lure: shape showing the space between the object and the walls of the pocket. The object

rest on the plane-Sketch. The plane-Sketch surface will serve as the "tab/tag" holding surface for milling of the second side. Details are provided at this link.

Image 3: Prototype executed with scrap material.

Waterline Fishing Lure:

Brief Summary of Project:

(OpenSCAD/Blender/FreeCAD) The STL/mesh file was grabbed from the earlier HeeksCNC effort. It was imported and converted into

shape/solid and eventually into a set of waterline NGC code. Waterline refers to the milling pattern that follows

the contours of the shape being milled. A run of saw dust was made using this

design to create the left side of the lure. The stock was then flipped and a second run executed. The

results demonstrated the "feasibility" of the design. But it clearly exhibited a need for additional layers

of waterline cuts and a need for closer control of the "flipped" origin. This original design was discarded

because too much "manual" effort was required to reconcile the right/left side mis-match. Plus the shape was

not an acceptable "lure".

Refinement of the waterline by increasing the granularity of the contour lines (depth of cut from -0.025 to

-0.010) did not provide a suitable quality to justify moving forward with this approach.

Image 4: Simulation Run in FreeCAD of Waterline and Finishing.

Discussion of Process Flow

The same STL that was imported to the HeeksCNC lure project was reused. The

import process steps for FreeCAD is the same as that used for the box/lid logo. Once the

The code shown below is ordered in the sequence used to mill the project.

- The "starter" CAD file builds the STL

- FreeCAD Waterline Fishing Lure design project.

- Waterline operation yields the surface shape of the lure

- Finishing operation removes material from around lure forming pocket

Tool Table Entries

- T16 P16 Z2.27855 D0.1275 ;1/8 x 3/8 double 2 flute

Collection of Helpful Images

Design to gCode Process Flow

This project reuses an existing OpenSCAD object. This object originally integrated a simple hull function in union with flat planar

surface. Once the object was designed and rendered it was exported as a *.STL file. The file was imported into FreeCAD as a STL mesh

entity. Sequentially that entity is converted to a shape, solid, refined shape, and finally a usable path shape. Once the path shape

was defined a "Job" was created with an ocl waterline operation and a finishing operation. The finishing operation first used a pocket shape to remove

stock material from region between the lure and a bounding box. The finishing operation completed its run by cutting an outline contour

outline of the lure. Tabs were not used since the planar surface was to serve as a base/wall between side 1 and side 2. As originally

planned side 1 would be milled first. Side 1 must also have index registration points to facilitate

flipping and milling of side 2. This will require extending the registration points through the work piece

to what will become side 2 milling surface. (Insure that the registration points do not mar the surface of

the region being milled.)

Side 1:

The waterline operation and the finish operation would run two separate gcode programs under LinuxCNC-Axis. But first the finish job would

be run without the stepper motors being engaged. Once this "virtual" mill job was completed LinuxCNC would display the

tool path executed except indicating a red

tool path . Then load the waterline. Us the "Touch Off" to jockey

X P1 G4 until a suitable

waterline aligns with the "finish" representation. Repeat for the

Y P1 G54. Continue to jockey the waterline

until a "best" balance appears. Try zooming/panning for better

resolution and jockey. Once satisfied run the waterline gcode program. After the waterline program executes, load and run the

finish program.

Side 2:

With Side 1 complete, flip the work piece/stock. Use the previously set index registration points of Side 1

set the physical location of the work piece. Start by loading/running the finish gcode without the stepper

motors engaged. Using the completed finish tool path align the waterline gcode and execute with the stepper

motors engaged. Then complete side 2 by executing the finish gcode.

Conclusion

As originally conceived the lure was to appear as a symmetric hull figure. If all went well, side 1 and side 2

should appear symmetrically spaced when viewed axially along the Z-Y and/or Z-X planes. The difficulty in alligning

the two sides precluded further movement down this avenue.

Complex Surfacing of Wooden Fishing Lure:

Brief Summary of Project:

(OpenSCAD/FreeCAD) A more nartual looking fishing lure has been designed using OpenSCAD with Bezier curve surfaces. The imported

STL mesh file was found to be too complex for PC resources. As a result no usable FreeCad shape was produce.

(OpenSCAD/Blender/FreeCAD) The STL model design effort of the lure shape was imported to Blender. This work is in process.

Image 5: Complex Fishing Lure in OpenSCAD (Flat Nose)

Image 6: Complex Fishing Lure Imported to FreeCAD (Round Nose).

Discussion of Process Flow

Subsequently discovered OpenSCAD "hull() function" and Bezier curved surfacing.

Design Supporting Artifacts

- Design code combines lure component shapes.

- Creates the surface patch for the under-belly of lure.

- Renders a generalized lure shape/surface created.

Design to gCode Process Flow

(OpenSCAD/FreeCAD) The generalized shape of a "crank" fishing lure was created using OpenSCAD. That shape was cut to create a more

realistic lure. The two components were then assembled into the lure shape. That shape was then converted to an *.stl file for

export. It was then imported itno FreeCAD where the complexity of the mesh shape became obvious. It proved to be impractical to

proceed along this approach.

A number of alternate approaches to obtaining a complex solid surface shape are being explored.

Wooden Box with Lid:

Brief Summary of Project:

The intent was to create suitable wooden boxes for general gifting. The project originally started by looking at creating puzzle

boxes with dovetail edges. But reality and CAD skill set collided. Once reality and complexity of FreeCAD's cubes and Path work bench

began to manifest itself, a decision made to slowdown. Then began the effort to make presentable wooden boxes with pockets and lids

with matching pads. The lids were to also have an appropriate logo/design artwork of minor complexity. That level of crafting was

captured in the following project.

Image 7: Box/Lid/Logo. Wooden pieces prior stain.

Discussion of Process Flow

- (FreeCad) The first run resulted in a usable box/lid. This run involved learning about the complexities of Sketches and setting

constraints. The default Zig-Zag pattern produced overly tedious clean-up work/sanding of the

pocket wall.

-

(FreeCad) A second run has been designed to mill more material from the stock for the pocket/pad. This run employed the original Sketch

from the earlier effort with resizing of the pocket/pad. The Offset milling pattern was

employed. Simulation under LinuxCNC demonstrated a cleaner approach. The simulation of the milling showed an issue with the placement

of the pocket and lid. Re-positioning of the pocket and lid within the virtual stock resolved that

issue. By re-positioning the milling was simplified. It also supported the pocket-pad matching without having to use the mirror or

to set other design features.

- (OpenSCAD/FreeCAD) A "radiant sun" image was designed in OpenSCAD as a 3D object and exported to FreeCAD as

an STL mesh model. The import went well resulting in body, shape,

solid, path shape, and pocket_shape.

Box/Lid Design Supporting Artifacts

- The supporting FreeCAD and OpenSCAD design project files for the box/lid are download-able as one

zip file.

- The mis-directed dovetail design approach project files are available as a zip file.

gCode for Milling

The resulting NGC gcode from FreeCAD and associated tool table are shown below. The current sizing is for a 6x4x1.5 box. The pocket and pad are roughly 5x3. The pocket is set to 1.3 inches depth. The pad is set to .375 inches.

- Box with pocket.

- Lid with pad. The thickness of the lid is left to the miller's

choice.

- Radiant Sun pocket.

Tool Table Entries

- T3 P3 Z1.273 D0.09375 ; 3/32 end mill Short Sherline 7002 for "radiant sun" logo.

- T18 P18 Z4.459 D0.233 ;1/4 router deep pocket for pocket, pad.

- Large surface removing bit via manual operation of the mill.

Design to gCode Process Flow

(OpenSCAD) The original box/lid involved dovetail edges and a circular pocket as shown the box and

lid CAD drawings. These drawings led to exportable *.stf files.

(OpenSCAD/HeeksCNC) Importing the two *.stl files from above produced the box_tab and

the box_slot projects. Although their where reflective of the intended design objective,

they appeared to be beyond the skill level available for the project.

(FreeCAD) As a good launch into FreeCAD a simpler "box/lid" with pocket/pad matching was initiated. As described and documented

above gcode was produced directly from FreeCAD and saw dust created. After receiving a request for

two more wooden box/lid this project was measured as a success.

Path Forward

- The box lid needs ot be tweaked just a bit to reduce the need for sanding the leading/lagging

edges.

- The next generation of box pocket/lid will employ a dovetail fit to slide the lid open/close.

- Additional "logos" will be added ot the collection.

Evolving a Practical Wooden Fishing Lure:

Brief Summary of Project:

(FreeCAD) A nartual looking fishing lure can designed using the various workbenches of FreeCAD.

This avoids the "resource hogging" associated with improting STL files of lures generated externally.

- Welling Lure Designshop

- Converting simple sketches(https://www.youtube.com/watch?v=7oOWvC80dNw) into complex solids

- Useful sketch and BSpline (https://owncloud.gwdg.de/index.php/s/HS2FD9s49wQs4fI) information/guidance.

Image 8: Post milling of first side of prototype lure.

Discussion of Desgin Process Flow

An original conceptual drawing of a fishlure must be manifested as a draft drawing. This

"lure draft" serves as the "2D container". The defined "lure draft" provides the outline and serves

as the boundary for the additional "shape defining layers". For this version of design four shape

defining layers were generated. At this point the shape defining layers were jockeyed into

appropriate locations to provided the required shape in 2D (X/Y Plane) and

constrained (see Image 9 below). Using the following Best Practices the

complexity of multiple sketches in a drawing surface is reduced.

- Practice with the sketch features before attemtping a "for record" run.

- Constrain as each sketch feature (lines, circles, BSpline, eclipses) is drawn.

- If a sketch is not immediately needed, hide it.

- Draw the structure of sketches in reverse order of the offset to be used like a pyramid. The

smallest sketch, the circle, was assigned to the top, The largest sketch, the outer trace

approximation of the Bezier shape was destined for the the bottom.

Image 9: Sketch of Level 1 (light green) and three sketches (white) overlaid on Bezier shape .

Once the shape defining layers have been constrained the offsetting and lofting can be

performed. The offsetting selected was a pyramid shape with the top layer being set at Z=0.0.

Subsequent shape defining layers were offset in the negative Z-axis. With the offsets defined

the Part was lofted to form "one side" of the lure.

Image 10: Lofted sketches render solid (planar view inverted to show sketch slices)

The generated loft shape of the lure was then submitted for Path Job Operations for waterline,

tabs-contour and pocket shape.

Design Supporting Artifacts

Once the lure has take its solid shape following lofting, it is ready to create the Job. With the

Job defined select the tooling and setup (material offsets and origin) to suit the mill shop and

stock material.

Waterline: Milling Lure Shape

Then define the first operation will define the lure as a 3D Surface solid. That operation was titled Waterline.

The second operation seeks to "free" the lure from the work stock material. For this specific lure

design's Waterline Operation, the starting height was established to be Z=0.0. The ending/lowest

depth was set to Z=-0.375. The cut dpeth was set to .0500. After simulation the depth of cut for

the circle feature was manually set to Z-0.0250.

Finishing: Freeing Lure From Work Stock

The second operation can be named Finish. The Finish Operation sequentially executes Pocket Shape

and Tabs/Contour. The start depth, finish depths, and step down cuts are consistant with those

used for Waterline.

Review of Waterline gCode

Generate the gcode and review the results. For the 3D Surface Waterline there is a specific

need to identify "extraneous loops" as shown in the next image below. An

extranepus loop does not "tie" to a specific waterline-contour. These extraneous loops

should be removed. Locating them is trivial. They typically occur near the point in the Waterline

gcode where step down cut depth changes (i.e where a the Waterline loop for a depth ends and a new

one begins). These loops are composed of relatively few lines of gcode.

Simulator Run: Two Issues Identified.

Simulation showed that a "very few number" of extraneous loops were missed. The identified

extraneous loops were removed. Simulation also showed that the circle had an illregular shape. The

shape was suitable for the prototype level of milling anticipated.

Tweaks to gCode

Note that the "%" charcter was added to the top line and the bottom of both *.ngc gcode files.

Appropriate comments/notes were also added for copyright and version history.

Code Artifacts for Milling

The resulting NGC gcode from FreeCAD and associated tool table are shown below. The current sizing is for a 6x4x1.5 box. The pocket and pad are roughly 5x3. The pocket is set to 1.3 inches depth. The pad is set to .375 inches.

- FreeCADC project file suitable for execution or downloading.

- Waterline gcode adjusted for milling lure shape.

- Finishing gcode for milling outline and removing material from pocket.

Design to gCode Process Flow

With a set of gcode (Waterline and Finish) it was time to move to the mill. The Waterline gcode

(with the "tweaks") ran without complaint the first time.

The Finish gcode required placement via Touch Off of X/Y G54 inorder to algin with the previously

milled lure.

After making the touch off adjustment, the gcode ran without incident.

Observations

There were two issues observed with the Waterline gcode.

- Moderate: The FreeCAD Waterline executed as a "topographical contour" cut rather than

as a waterline/level cut. The expectation was that it would remove all the stock material within

the basin of the lure shape for the Z depth value. Since the prototype lure mill was executed in

soft wood the End Mill/Spindle had no significant difficulty. Workaround The work around

is to return to the Waterline cGode and use the approach that has previousl been employed to

assmeble a "composite" of the lure's Waterline toolpaths into one o-code loop. Then on each

pass of the loop the step-down cut value would be decremented to meet the water line/level.

This will increase to execute each exection time. But it will save the stress on the mill.

Original Observation/Issue of single mill cut per depth.

Post Adjustment to gCode using o-loop flow control and user defined variables.

For a level multiple toolpath cuts per depth remove material along "waterlevel" of work basin.

- Minor: The Waterline gcode failed to "remove" material ("excess material) from the shape

of the lure in three places. Workaround The excess materail was removed with little effort

using tools on-hand in the shop. But it is risky.

There was one issue with Finish gcode.

- Minor: The four Tabs failed to materialize as the outline contour executed.

Workaround This was acceptable at this level of prototype. But it needs to be

examined before moving to far forward. This aspect will become increasingly important as

the lure moves into a left side/right side mirroring design/job.

Creating a Realistic Wooden Fishing Lure:

Brief Summary of Project:

This project, 016_fishlure, employed previously gained FreeCAD knowledge, experimentation with FreeCAD Draft and Parts workbenches, and new milling

skills to produce a very realisitic shaped crank style lure.

Image 11: Realistic Wooden Lure ready for painting, hardware, and water trials.

Field Testing

The lure created from the following process has been "pond tested".

General Observations

Responded well to casting

Good distance

Good control even in light wind

Dual trebble hooks played well

Cranking/Playing

Settled evening in water

Pulled evening/straight in water

Responded with diving/wiggle

Worked through vegetation

Durability

Sealant/colors held fast

Pulled sizable tree branch along surface

Comparison with Other Crank Lures

Similar Crank Shape

Ultra-Light sample

Twice as heavy as sample

Confirmed need for dive lip

Conclusion

Good to fish

Create three more for prototyping

Add dive lips to prototype

Defer Decision

Scale of shape

Discussion of Process Flow

The FreeCAD project files, resulting gcode, and salient configuration files for the Sherline

Next Generation 8580 with Rotary Table/Right Angle are given below in compressed file format.

- FreeCAD project files for Lure and Finish Operations.

- Compressed file collection of gcode for milling the

lure objects.

- Configuration files in compressed format

to support milling the lure and finish operations.

Tool Table Entries

- T16 P16 Z2.321 D0.1275 ;1/8 x 3/8 double 2 flute

"stepper.var" Entries

5220 1.000000

5221 0.000000

5222 -0.600000

5223 -2.000000

5224 0.000000

5224 0.000000

Discussion of Design Process Flow

See the earlier crank lure for a preliminary

discussion and first baby steps towards a realistic crank lure design.

Side-1/Side2:

The initial steps in the design followed the same basic process as the earlier crank lure

desgin for Side-1. The "tricky" point was creating a symmetrical matching object, Side 2,

that could be milled. This side would need to be milled from the same work stock but with

a different orientation. This "effect" was generated during the design phase by mirroring

the Side-1 solid model. That sounded simple. But multiple passes at attempting to produce

Side-2 proved to be a problem. The solution involved capturing the toolpath for Side-1 as

the "model" of the solids surface. The generalized design process steps are given below:

Side-1

Begin with the Draft Workbench

Create a Construction group

Within the new group create

outlines of desired layers

Take advantage of undocumented

feature/bug and ignore

non-constrained layers

Position layers as if viewing from side of lure.

From the Part Workbench

Create sphere and place it as the eye of the lure.

Fusion of the lure/eye as a Model.

From the Path Workbench

Create a Job Side-1

Use Fusion as Model

Setup Stock/Tool

Use Waterline

Set start depth at 0.0 inch

Set final depth as needed.

Set parameters as needed

Select Waterline

Double check post-OK

Reset in Model.Data

be OCL Waterline.

Create waterline toolpath

Side-2

With the

Side-1 Base-Fusion Model displayed head-on.

Part Workbench Mirror in XY plane

Draft Workbench Rotate 180 Clockwise

In Path Workbench

Create Job-Side-2

Post Process Lures

Post Process Lure

Generate Side-1 gcode

Generate Side-2 gcode

Adjust both ngc files as needed

Finish Ops

Create Simple Finish Objects

Create Side-1 Finish Job

Use Extrude_Lure as Model

Create Pocket_Shape Op

Create TagDressup/Contour

Generate Side-1Finish gcode

Create Side-2 Finish Job

Use Extrude_Lure (Mirror) as Model

Create Pocket_Shape Op

Create TagDressup/Contour

Generate Side-2 Finish gcode

Move To Mill

Customize gCode

Add custom version control/history

Add custom content

Simulate Milling Operation

Practice Probe of Centerline

Practice Flip and Reset

Create Cutout Paths

From LinuxCNC/Text Editor

Create TagDressup/Contour Cutout

Design to gCode Process Flow

With a collection of nine gcode files the project was moved to the mill. The Probe file was

replaced with a level and a "scribe" point engraver to verify centerline on top. Then

the work stock was flipped and the bottom centerline was verified. Verification of

both top and bottom centerlines involved moving in the X axis along the centerline

and "touching at several points. The combination of the 4-jaw chuck, right angle, level,

centerline, and engraver/probe produced excellent results.

Sequence of Milling Steps:

- Level, Setup Centerline, and Verify

- 089.01_01_016_970_fishlure_waterlineEye.ngc

- 089.02_07_016_495_fishlure_waterlineFinish.ngc

- 089.03_01_016_980_fishlure_flipper.ngc

- Shutdown LinuxCNC and Restart As Is

With Side-2 "now" facing the end mill

- 089.04_01_016_970_fishlure_mirrorEye.ngc

- 089.05_05_016_495_fishlure_mirrorFinish.ngc

- 089.03_01_016_980_fishlure_flipper.ngc

- Shutdown LinuxCNC and Restart As Is

With Side-1 "now" facing the end mill

- 089.07_04_016_999_fishlure_TabContourCutOut.ngc

- 089.08_05_016_999_fishlure_boxCutOut.ngc

Project Photo Gallery:

Click Item to Expand

Through-Wire Wooden Fishing Lure:

Brief Summary of Project:

This project, 021_fishlure, employed previously gained FreeCAD knowledge, experimentation with FreeCAD Parts.Revolve workbench.tool, incorporation of four flute endmills, and cable wrapping loops. The results, lure style 021.4, is a stronger, realistically shaped crank style lure. Fish actually took an interest in this prototype.

Pond testing, lure confirmed the need for a lip. Various lip designs were attempted using materials such as plexiglass and thin sheet metal. Finally a potential, feasible 3D printer

design was discovered. However, that design was determined to be too difficult to insert/mate with the 021.4 style lure body. A modification of that 3D printer design and of the 021.4 style lure was employed. A discussion of the modifications to the lip's 3D design can be found as a "make" of the original lip design. The FreeCAD project 021 was modified to include a pocket cut on the bottom of the lure to support mating with the lip with a modest negative three degree drop. The documents for the 3D printer lip and the pocket cut are provided further below in this section.

Image 11: Realistic Wooden Lure ready for assembly, final expoy coating, hardware, and water trials.

Field Testing

The 021.4 style lure has completed "pond tested".

Prototype:

016.2.1. FreeCad Project 016. Two Flute First Example

021.2.1. FreeCad Project 021. Two Flute First Example

021.4.1. FreeCad Project 021. Four Flute First Example

021.4.2. FreeCad Project 021. Four Flute Second Example

| General Observation

| 016.2.1

| 021.2.1

| 021.4.1

| 021.4.2

|

Responded well to casting

Good distance

Good control even in light wind

Dual trebble hooks played well

Cranking/Playing

Settled evenly in water

Pulled evenly/straight in water

Responded with diving/wiggle

Worked through vegetation

Durability

Sealant/colors held fast

Drag tree branch long surface

Comparable to other crank lures

Classic crank lure shape

Ultra-Light sample

Relative weight to sample

Confirmed need for dive lip

Response From Fish

Hits/Bites

Caught/Landed

Conclusion

Good to fish

Create three more for prototyping

Add dive lips to prototype

Defer Decision

Scale of shape

|

No(1)

Yes

No

Yes

Yes

Yes(2)

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

No

Yes

No

NA(3)

NA(4)

NA(4)

|

Yes

NA

Yes

No(5)

No(6)

No(7)

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

No

Yes

Yes

No(4)

No(4)

No(4)

|

Yes

NA

Yes

No(5)

Yes

No(7,9,11)

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes(8)

Yes

Good2Go

Yes(9)

Good2Go

Yes

|

Yes

NA

Yes

No(5)

Yes

No(7.9.10)

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

No

Yes

Good2Go

Yes(9)

Good2Go

Yes

|

1. Ballast weights added to lower buoyancy.

2. Responded well with lip added.

3. Added lip since first pond trial.

4. Terminate design development.

5. Too buoyant.

6. Slight yawl/roll as cranked

7. Needs lip.

8. Large mouth bass landed on third cast.

9. Retrofit dive lip.

10. Lip added and pond tested.

11. Lip added and given to associate for testing.

|

Discussion of Process Flow

The FreeCAD project files, resulting gcode, and salient LinuxCNC support files for the Sherline

Next Generation 8580 with Rotary Table/Right Angle are given below in seven part compressed file rar format. A high level view of contents of the compressed files is given directly below. Links in the next section lead to the downloadable seven compressed files.

- A file called dirlist which provides a working manifest of the zip file.

- Folder containing a more detailed a working checklist for moving through the milling process.

- FreeCAD project files for Lure and Finish Operations.

- The full collection of gcode for milling the

lure objects.

- A folder containing supporting program modules with images which require loading to the LinuxCNC machine folders.

- The Cura 3D printer design project and gcode are available from the lucca82 Make Project at Thingiverse. That site also contains a discussion directly related to the 3D Printer aspect of the lip for the lure.

Download Actifcats

- Part1

- Part2

- Part3

- Part4

- Part5

- Part6

- Part7

gCode For Lure Milling:

gCode

Filename

| Purpose

| Comment<

|

| 081.15_07_009_980_fishlure_probe.ngc |

Execute a probe along centerline |

Performed manually. |

| 089.03_02_016_980_fishlure_flipper.ngc |

Flip workstock from 0 to 180 degrees |

Executed well |

| 089.06_02_009_980_fishlure_reset.ngc |

Flip workstock from 180 to 0 degrees |

Executed well |

| 092.01_06_021_973_057_ure_SideA_Top.ngc |

Executes waterline surface milling of SideA |

Executed well |

| 092.02_06_021_973_057_lure_SideB_SplitFace.ngc |

Executes SideB milling for through wire placement |

Performed manually. |

| 092.03_04_021_973_057_lure_SideB_Bottom.ngc |

Executes waterline surfacemilling of SideB |

Executed well |

| 092.04_06_021_973_057_PinHoleOnly_lure_SideB_SplitFace.ngc |

Drills Pin Holes for SideB |

Performed manually. |

| 092.99_05_021_973_057_outline_lure_SideB_Bottom.ngc |

Creates trace outline of SideBfor lip alignment |

Executed well |

| 100.01_08_031_973_057_lipCut3dPocket_boxCheck.ngc |

Executes the pocket cut for lip |

Executed well |

gCode Filename syntax

ggg.ss_vv_fff_ppp_xxx

ggg: Identifier for gcode folder/family repository

ss: Identifier for gcode within a folder/family

vv: Revision numeric

fff: FreeCAD project workspace

ppp: Project within a FreeCAD project workspace

xxx: Identifier assigned to a hybrid of a Project

|

|

|

Tool Table Entries

- T21 P21 Z1.273 D0.045 ;dremel scribe engraver added 20190502

- T22 P22 Z4.013 D0.0625 ;dremel 1/16 drill

- T23 P22 Z4.013 D0.0725 ;dremel 3/32 drill

- T24 P24 Z2.264 D0.1275 ;1/8 x 3/8 4flute

- T25 P25 Z0.0 D0.25; 1/4 x 38 2 Flute End Mill Hand Powered

"stepper.var" Entries

5220 1.000000

5221 0.000000

5222 -0.605000

5223 -2.000000

5224 0.000000

5224 0.000000

Discussion of Design Process Flow

See the earlier crank lure and

realistic lure for a discussion of the maturing steps in crank lure design. Instead of using a Side-1 and

Side-2 (Right Half and Left Half) the perspective was changed to Dorsal {Top} Half and Belly {Bottom} Half.

This change allows the compartmentalization of the design. The Dorsal Half has both eye buds and the primary

shape of the lure. The Belly (Bottom} Half features include the Through Wire, the Belly Hook Loop Wire,

and Alignment Pins Holes.

Dorsal Half/Belly Half:

The initial steps in the design differed from the earlier crank lure of Project 016. The Dorsal or Top Side

was based upon an ellipse 2D shape. Using this shape as the outline, a continuous multipoint DraftWire 2D line

was drafted from the left most point touching the x-axis to its right most point touching the x-axis. Using the

Draft bench-revolve, the 3D Dorsal Half was created. With the Dorsal Half defined, it was then copied/pasted as

the Belly Half. With the Belly Half shape now available, the Belly Half was modified from within the Draft

workbench to generate the "desired" shape.

From that point forward the Dorsal Half and Belly Half were available for creation of Jobs and the associated

*.ngc code. The Through Wire Processing was originally attempted as a separate CAD/CAM CNC gcode process. But

common sense that it was better to create the Through Wire grooves, drill Belly Holes, Alignment Holes, "custom

fit" craving of gaps for wire wraps manually, and adding a pocket cut to provide mating surfaces with the plastic lip. NOTE: For this early prototyping of the 021.4 style lure, the pocket cut was executed post-bandsaw separation because the need for the lip had not been confirmed. The difficulty in the alignment curved body lures presented with this deferred pocket cutting of the prototype strongly suggested that this pocket needs to be cut prior to the waterline surfacing while the centerline and factory edges of the woodstock can be employed.

A bandsaw was employed to separate the Dorsal Half and Belly Half from the workstock. The Dorsal Half and the Belly

Half were then placed in a vise (with sacrifice wooden bumpers) to allow the drilling of the two alignment holes. The

original centerlines (now significantly shortened) of the Dorsal Half were used for the drill operation setup.

Once the Alignment Pin Holes had been completed the two halfs were separated and then re-assembled. During the

re-assembly, the Belly Half was now placed above the Dorsal Half such that the Alignment Pins could be inserted to

allow exposure of the Belly Half's split face matching surface. With the Belly Half's matching surface exposed its

centerline could be roughly verified between the head and tail points along the x-axis. The lures Through Wire

groove was then scribe to a sufficient depth to allow the wire to just reach the top of the surface. The Belly Hook

hole and its associated wrap "bore" hole were drilled. The accompanying "howto zip package" will provide a more detail set of steps as well as the pocket cut gcode and additional files to support this new operation.

The two lure halves were removed from the vise. The Through Wire Loops and Belly Hook Loops were created, assembled,

and installed. Clearance "bore" holes were identified and created as needed to allow a "good" fit between the two

halvs. This required a couple of assembly attempts using the Alignment Pins and then gently separating. During

separation the both halves were examined to locate any points of conflict that might require additional "boring/cutting".

Once a "good" fit was achieved with the two halves and alignment pins were epoxied bonded. The excess lengths of the

alignment pins were allowed to protrude from the Belly Half while being tangent with the Dorsal Half's surface. Painting

coats were added as each dried. Avoid placing paint on the lip mating surface of the lure. Once the lure has dried the lip is ready to be epoxied into place. After that mating joint has cured a slanted slightly off-centerline pre-drill hole should be made such that the lip is pulled toward the mating surfaces of the lure. A small wood screw should then be fully inserted and then sealed. The body of the lure, immediate mating of the lip, and the lip's screw should then be receive sealant coat. The lure hardware was added after a "full" sealant cure in a solar oven.

Dorsal Half

Begin with the Draft Workbench

Create a Construction group

Within the new group create

ellipse

Use the ellipse's Major/Minor Radius(from the Model)

Use Draft.Draft To Sketch to create a

sketch version of this figure.

Take advantage of undocumented

feature/bug and ignore

non-constrained layers

From the Part Design Workbench

Create a New Body called "TopHalf"

From the Part Workbench

Add the Dorsal Half solid to this new Body

Create sphere and place it as the right eye of the lure.

Create sphere and place it as the left eye of the lure.

Fusion of the lure/eyes as a Model.

From the Path Workbench

Create a Job Dorsal Half

Use Fusion as Model

Setup Stock/Tool

Use Waterline

Set start depth at 0.0 inch

Set final depth as needed.

Set parameters as needed

Select Waterline Operation

Note that the Project 021 uses either Four Flute

End Mill for milling the surface.

Setup Contour Operation

Setup Dressup Tags Operation

Belly Half

Begin with the Draft Workbench

Use the existing Construction group

Paste this sketch

Rename this sketch for use on the BellyHalf

Double click this sketch to invoke the Sketch Workbench

Modify outline sketch to suit.

Drag it a little and place in a new position.

Then grab and drag the next point.

From the Part Design Workbench

Create a New Body called "BottomHalf"

From the Part Workbench

Add the Belly Half solid to this new Body

From the Path Workbench

Create a Job BellyHalf

Use Belly Half solid as Model

Setup Stock/Tool

Use Waterline Operation

Set start depth at 0.0 inch

Set final depth as needed.

Set parameters as needed

Select Waterline Operation

Note that the Project 021 uses either Four Flute

End Mill for milling the surface.

Setup Contour Operation

Setup Dressup Tags Operation

Lip Pocket Cut

Begin with the Part Workbench

Convert Lip STL model to a Mesh model.

Convert Lip STL Mesh model to a Solid.

Use the Previously create belly bottom

From the Draft Workbench

Create the Actual Cut Pocket Model

From the Part Workbench

Continue development of the Actual Pocket Cut Model

Encase the cut model in a workstock block suitable to reflect

From the Job Workbench

Create a Job using the Pocket Cut Model as the Job's model

Under Operations Select 3D Pockets

For Depths Start Depth

select default and set

later. Set Finish and Step Down to suit.

For Heights and Operation select select the best for your equipment.

From the Combo View select the 3D Pocket operation

Once entered FreeCAD will begin a round of calculations

Post Process Lure

Generate Dorsal Half gcode

Generate Belly Half gcode

Generate Belly Outline gcode

From a text editor import a copy of the Belly Half gcode

Delete all Dressup and Surface gcode except for the last waterfall loop.

For the identified last waterfall loop perform a global Z

replacement such that Z now has a minimal depth

cut. For example Z=-0.01 in.

Save this document as the Belly Outline gcode.

Generate Lip Pocket Cut gcode

Adjust both ngc files as needed

Customize gCode

Add custom version control/history

Add custom content

Simulate Milling Operation

Practice Flip and Reset

Simulate Dorsal Half Waterline and Contour/Dressup

Simulate Belly Half Waterline and Contour/Dressup

Simulate Belly Outline and Lip Pocket Cut

Design to gCode Process Flow

With a collection of nine gcode files the project was moved to the mill. The Probe file was

replaced with a level and a "scribe" point engraver to verify centerline on top. Then

the work stock was flipped and the bottom centerline was verified. Verifcation of

both top and bottom centerlines involved moving in the X axis along the centerline

and "touching at several points. The combination of the 4-jaw chuck, right angle, level,

centerline, and engraver/probe produced excellent results.

For a detailed, stepwise description of "how-to" create the lure from the CNC

Mill to painting/coating and lip assembly view the process steps"how-to" document.

Project Photo Gallery:

Click Item to Expand

NOTICE: This site was fabricated for best viewing using

Netscape 4.x, or a functionally

equivalent browser.

Please send comments or questions using e-mail, voice telephone at 919-846-7705. (Last update: October 10, 2019 tar)